How a sensor built for satellites became a tool for real-time skin-dose verification.

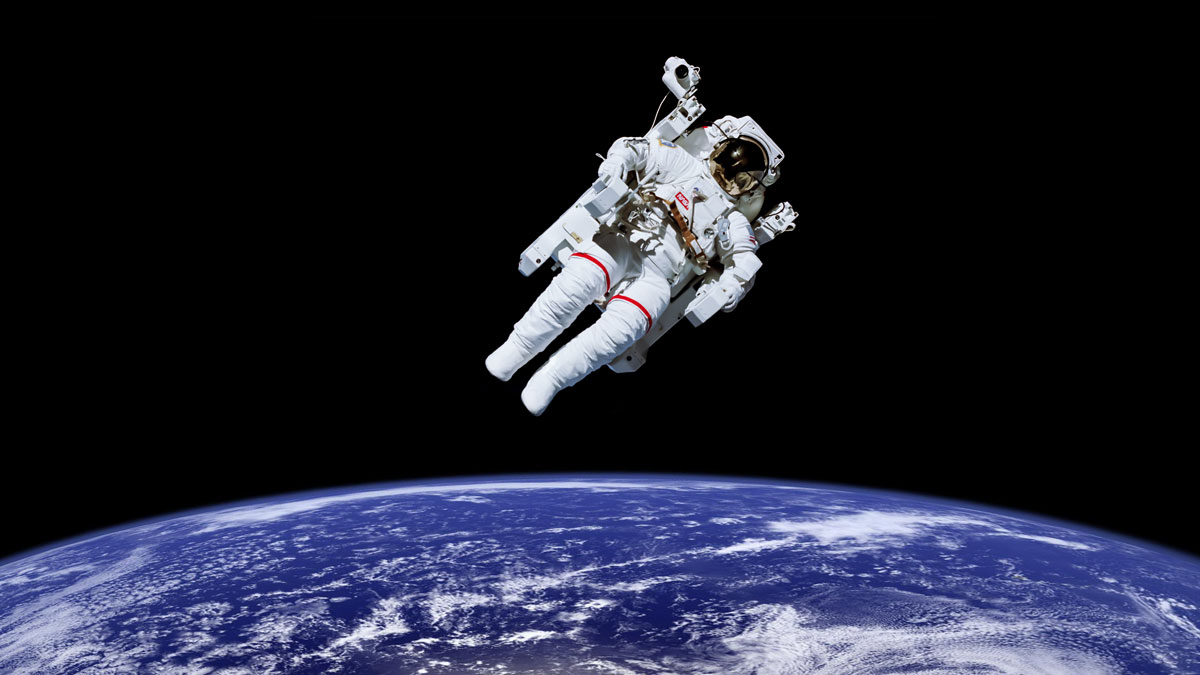

Long before MOSkin was used in clinical environments, its core technology started in a very different place — orbit.

The original concept was developed for space missions, where understanding radiation exposure is essential for protecting satellites and ensuring mission reliability. Space environments demand sensors that are incredibly small, highly sensitive, and able to measure radiation in real time. Those requirements shaped the earliest version of the MOSkin architecture.

At the University of Wollongong’s Centre for Medical Radiation Physics, Professor Anatoly Rozenfeld and his research team pioneered this miniaturised MOSFET-based dosimetry platform. Their work focused on creating sensors that could withstand extreme conditions while capturing precise measurements without delay. That same DNA now underpins the MOSkin system.

When the technology transitioned from orbit to oncology, the match was natural. Clinical teams needed the same things:

- Dose readings within minutes

- A sensor thin enough not to disturb the field

- Confidence that the measurement aligns with the depth of interest

- A dependable platform built for demanding environments

The challenge wasn’t redesigning the sensor — it was adapting a space-proven idea into something practical for busy clinical workflows. Through years of refinement, engineering collaboration, and validation, MOSkin evolved into the world’s smallest smart dosimetry sensor, built to give clinicians clear and immediate insight into skin-level dose.

Today, the outer environment has changed, but the principle is the same: when accuracy matters, real-time measurement matters. And sometimes the best clinical innovation starts far beyond the clinic.